Precision Machining Services

Precise Machine Company offers precision machining services of high-tolerance machined parts for any industry across the United States. We accept single lot orders and blanket orders. We also offer value-added services, including anodizing, chem film processing, part marking, and mechanical testing. Contact us today to get more information or to request a quote.

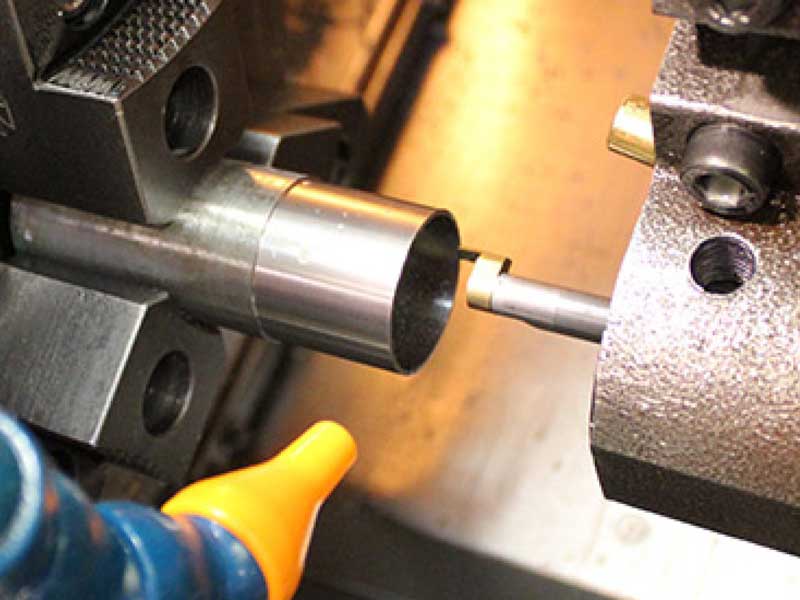

CNC Machining

Learn More

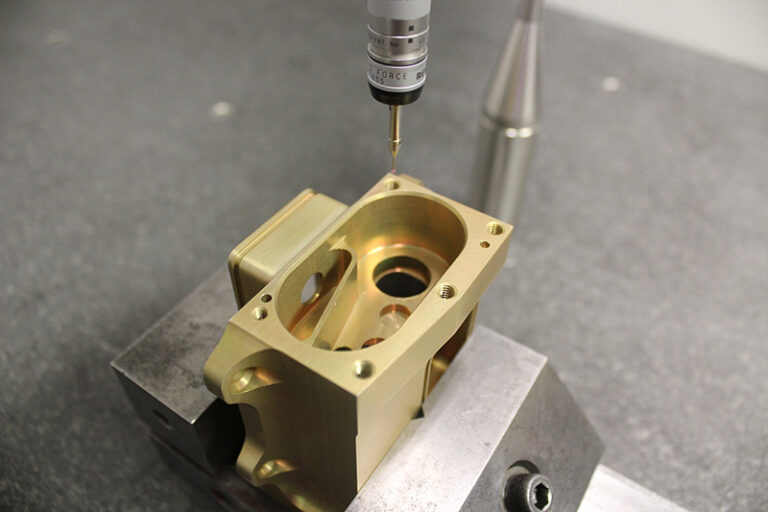

CNC Quality Control & Inspection

Learn More

Value Added Services

Learn More

Assemblies That Meet your Exact Requirements.

Competitively Priced

Delivered On Time

Decades of Experience & Expertise

Benefits of Our Services

Our shop features CNC machines from industry-leading brands, including Doosan, Haas, and Fryer. We also use top-of-the line accessories, such as Northfield air chucks to protect sensitive, thin-walled parts and components during the machining process.

Our equipment is operated by a skilled and knowledgeable team with over 150 years of combined experience in CNC milling, turning, and jig boring. You can trust that Precise Machine Company will deliver high-quality machined components that meet or exceed your needs, while remaining competitive on price and delivering your parts on time.

Materials

Our capable staff and collection of CNC machines can accurately mill, turn, and jig bore parts and components made of most metals and super alloys, including aluminum, stainless steel, brass, titanium, and Inconel.

Alloy

Learn More

Aluminum

Learn More

Brass

Learn More

Copper

Learn More

Stainless Steel

Learn More

Titanium

Learn More

Ready to Get Started?

Contact us today for more information about our CNC machining services and to request a quote. You can send us a message or call us directly at 847-647-7117 (select option 2). We are available Monday through Thursday, 8:00 AM to 5:00 PM CST, and Friday from 8:00 AM to 12:00 PM

Contact us Today